Decontamination process

From their arrival, the transformers are registered and given a unique internal number to make them fully traceable.

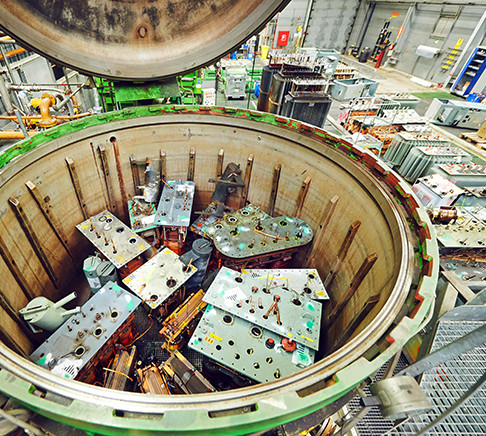

The decontamination process begins here:

Our production process aims at separating the metals from the other contaminated materials.

These metals are then completely cleaned and can be recycled. The quality of the metals is checked on a regular basis by a licensed laboratory.

From their arrival, the transformers are registered and given a unique internal number to make them fully traceable.

Their oil is pumped out and stored before incineration in our fully permitted plant.

After the transformers have been opened, the cores are separated from their casings before decontamination in our autoclaves.

The solvent that is used in our decontamination process is distilled by us in order to be reused in our production cycle. After cleaning, the metals are recycled. The other waste (paper, wood and cardboard) are incinerated in fully permitted and audited facilities.

About us

Since 1995, PCB Decontamination in Grimbergen treats electrical devices which have been contaminated by PCB (polychlorinated biphenyls) and recycles its metal content.

PCB Decontamination aims to offer a global solution for all the PCB containing devices, which must be made unusable in accordance with the Stockholm Convention , in order to be destroyed permanently.

It basically concerns distribution transformers, but also capacitors, oils containing PCB and other PCB-contaminated products. The treatment method allows recovering the metals and allows ensuring the destruction of the PCB or oils contaminated with PCB in an approved disposal centre.

What we do